Understanding Printed Circuit Boards (PCBs)

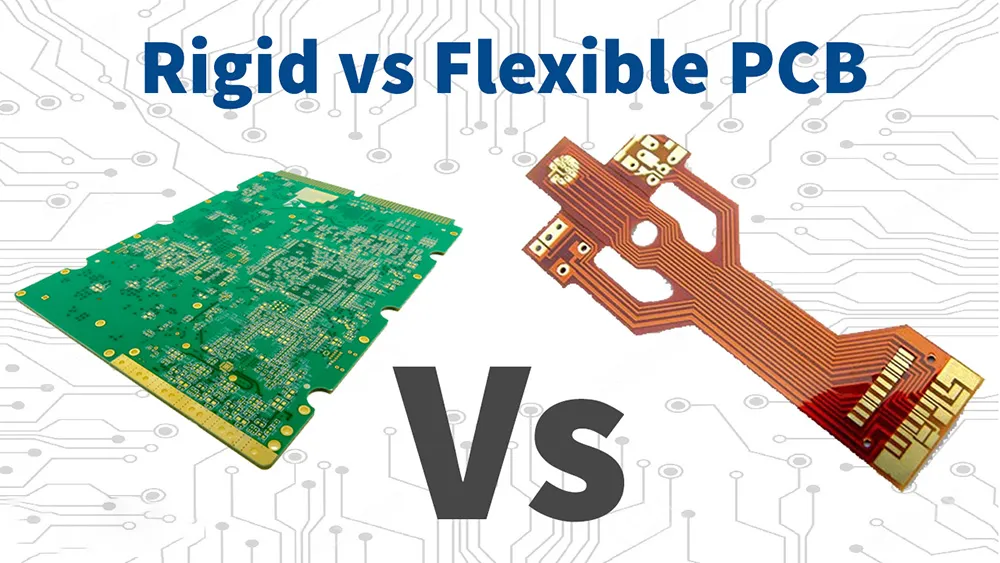

Printed Circuit Boards (PCBs) are the backbone of modern electronics, providing a platform for components to connect and function seamlessly. PCBs have evolved significantly over the years, and two prominent types have emerged: Rigid PCBs and Flexible PCBs.

What are Rigid PCBs?

Rigid PCB is the traditional and most widely used type of PCB. They consist of a solid substrate, typically made from fiberglass-reinforced epoxy, providing excellent mechanical support for components. Rigid PCBs are designed to be inflexible and maintain shape, making them ideal for applications where dependability and sturdiness are paramount.

Applications of Rigid PCBs

Rigid PCBs are used in:

- Computer motherboards: The main circuit board that connects all the parts of your computer.

- Modern hardware: This includes devices like:

- Laptops

- Tablets

- Smartphones

- Gaming consoles

- Automotive systems: This includes parts like:

- GPS navigation systems

- Entertainment systems (like radios and infotainment systems)

- Safety features (like airbag systems and anti-lock brakes)

- Industrial control systems: This includes machines and devices that control and monitor industrial processes, like:

- Factory automation systems

- Robotics

- Medical devices

Rigid PCBs are chosen for these applications because they are:

- Reliable

- Durable

- Able to withstand harsh environments

- Able to support heavy components and high currents

This makes them ideal for use in devices and systems that must be robust and long-lasting.

What are Flexible PCBs?

Flexible PCBs, or flex circuits, are unique printed circuit boards that bend and flex without breaking. They are made from flexible plastic materials like polyimide or polyester, which allow them to move and twist without damaging the circuitry. This makes them perfect for small spaces or applications where flexibility is essential, like in wearable devices, medical equipment, or aerospace technology. They can be folded, rolled, or shaped to fit into tight spaces, making them very useful for designing compact and portable electronic devices.

Applications of Flexible PCBs

Flexible PCBs are used in many exciting areas, including:

Aerospace: Flexible circuits help make aircraft and spacecraft lighter and more efficient. Medical devices are used in heart monitors, blood glucose meters, and portable defibrillators.

Wearable technology: Flexible PCBs enable flexible and comfortable smartwatches, fitness trackers, and bright clothing.

Consumer electronics: They’re used in devices like smartphones, tablets, and laptops to make them thinner and more flexible.

In short, Flexible PCBs help make electronic devices smaller, lighter, and more flexible, which is especially important in industries where space and weight are crucial.

Key Differences between Rigid and Flexible PCBs

1. Flexibility:

Rigid PCBs are stiff and can’t bend.

Flexible PCBs can bend and flex easily.

2. Material:

Rigid PCBs are made from strong, solid materials.

Flexible PCBs are made from flexible plastic materials.

3. Applications:

Rigid PCBs are great for devices that must be strong and sturdy.

Flexible PCBs are perfect for devices that need to be small and flexible.

4. Cost:

Flexible PCBs are usually more expensive than Rigid PCBs.

5. Durability:

Rigid PCBs can withstand rough handling and last longer.

Flexible PCBs are more prone to damage and have a shorter lifespan.

In short, Rigid PCBs are solid and sturdy, while Flexible PCBs are flexible and perfect for small spaces. However, Flexible PCBs are more expensive and less durable than Rigid PCBs.

Step-by-Step Guide to Choosing the Right PCB

Step 1: Determine the application: Think about what you’re trying to build. What will it do? What features do you need? This will help you decide what kind of PCB you need.

Step 2: Consider flexibility: Will your device need to bend or flex? If so, you’ll need a Flexible PCB. If not, a Rigid PCB will work.

Step 3: Assess durability: Will your device be used in a rough environment? Will it be exposed to water, dust, or extreme temperatures? If so, you’ll need a Rigid PCB, which is more durable.

Step 4: Evaluate cost: PCBs can vary in price. Balance the cost with what your device needs to do. Don’t sacrifice performance for a cheaper price, but don’t overspend if you don’t need to.

Consider these factors to choose the right PCB for your project. The right PCB will help your device work correctly, last longer, and meet your needs. If you want to learn more about right PCB for your need you can have complete guidline and complete range of PCBs at https://kingsunpcba.com/

Conclusion

Think of it like building a house. It would help to have the suitable materials and tools to make it solid and functional. Similarly, when creating an electronic device, you need a suitable PCB to work correctly and last long. Rigid PCBs are like a house’s strong foundation and walls, while Flexible PCBs are like flexible pipes and wires that bend and adapt. By choosing the right PCB, you’re ensuring that your device has a solid base from which to work and can perform its functions without fail. It’s a crucial decision that can make or break your project, so taking the time to get it right is essential!