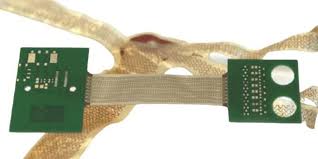

The technology has been enhanced with flexible and stretchable PCBs, making it possible for wearable electronic devices to bend and stretch, enabling wearables to scale with the shapes of the human body.

How Flexible and Stretchable PCBs Differ from Traditional PCBs

Materials:

- Unlike rigid PCBs made of simple carbon grease, flexible and stretchable PCBs are made of polymer materials, including polyimide, PET and silicone, and are capable of being stretched to many times their original length.

Mechanical and Electrical Properties:

- This type of PCB can stretch without breaking or chewing on electronic connections because of its mechanical properties.

Design Differences:

- Stretching and repeated movement along the same paths keeps components against sensors and traces aligned, preventing circuit damage.

Applications of Flexible and Stretchable PCBs in Wearables

Fitness Trackers and Smartwatches:

- Easy to bend and stretch, Flexible PCBs are perfect for curved designs.

Medical Wearables:

- ECG patches and glucose monitors shape perfectly to the skin thanks to the stretchable PCBs.

Electronic Skin (or E-Skin):

- Thin film and flexible PCBs with ultra-flexible wires are currently used in e-skin for applications in prosthetics and robotics.

Smart Clothing:

- Stretchable PCBs embedded in textiles can supply biometric readouts and physically track patients during rehabilitation.

Key Benefits of Using Flexible and Stretchable PCBs

Improved User Comfort and Mobility:

- Conformable designs enhance comfort and allow for natural movement.

Enhanced Device Durability:

- Resistance to bending, twisting, and environmental factors ensures longevity.

Flexible PCBs fit the user like a glove: ready-tote-able devices that can be slipped into a pocket or bag with ease. Most current wearables have their origins in a time before the modern convenience of printed circuit boards were invented.

Challenges in Manufacturing Flexible and Stretchable PCBs

Material Compatibility Issues:

- Maintaining conductivity while stretching inelastic substrates can be challenging.

Complex Fabrication Processes:

- Manufacturing requires precise lamination and etching techniques.

Balancing Performance and Flexibility:

- Increasing flexibility may compromise electrical performance.

Innovations and Trends in Flexible PCB Technology

Liquid Metal Circuits:

- Gallium-based alloys offer superior flexibility and conductivity.

Biocompatible Materials:

- Materials suitable for skin contact are essential for medical wearables.

3D Printing and Additive Manufacturing:

- Speedy prototyping of complex geometries is made possible.

Future of Wearables with Flexible and Stretchable PCBs

They’re out there, and on the horizon. And they will become more comfortable and functional and versatile, thanks to a continuing advancement of stretchable and conformable materials, manufacturing methods, and integration with other technologies for wearables, including bracelets, T-shirts, or even underwear.

FAQs

Describe the main differences between flexible and stretchable PCBs:

- Flexible PCBs are bending, while the stretchable PCBs are capable of stretching and returning into the original shape.

And they work: how many years do wearables with elastic PCBs last?

- Years, if you take care.

Can flexible PCBs withstand water exposure?

- Many are coated with waterproof materials.

Will flexible and stretchable PCBs be recycled?

- Some of the components can be recycled, but the process is not very simple.

For high-quality Flex PCB manufacturing and assembly, visit rushpcb.co.uk to see how we can elevate your project.